Are you searching for the quietest air compressor Australia has to offer? Look no further! In this article, we will explore the world of air compressors, exploring top-notch options known for their whisper-quiet operation. Whether you operate as a professional contractor or are a do-it-yourself enthusiast, your work experience can be greatly improved by selecting the ideal air compressor that blends power with tranquility.

Join us as we unveil the most advanced and peaceful air compressors available in Australia, ensuring you find the perfect match and service for your needs.

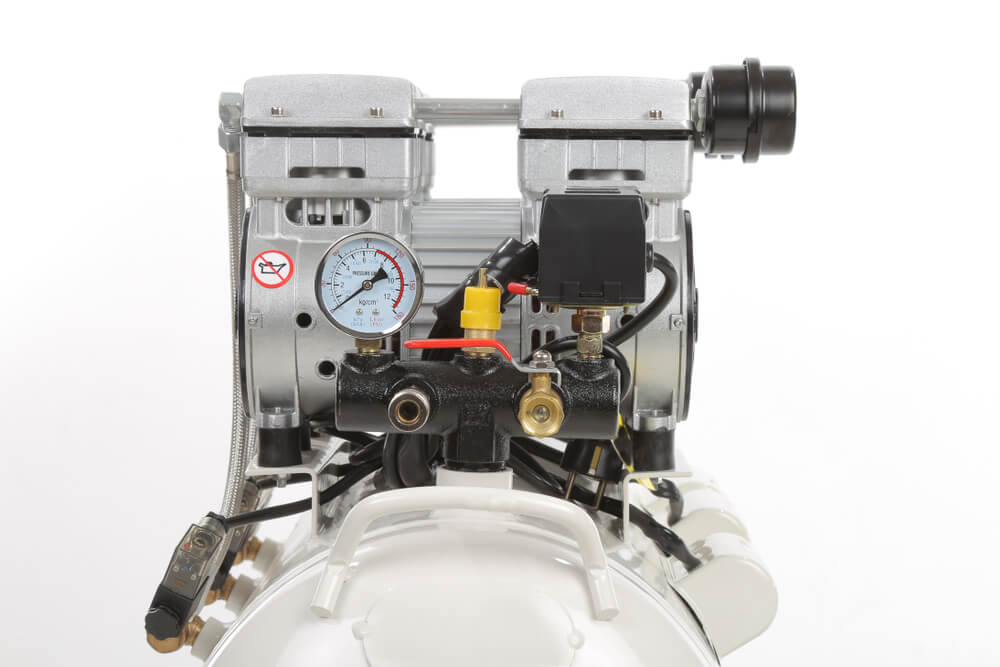

Comparing Silent Air Compressors with Traditional Models

In Australia, the choice between silent air compressors and traditional models is significant, especially for users prioritising noise reduction alongside performance. Understanding the differences between these two types of silent air compressors can guide consumers to make informed decisions based on their specific needs.

Noise Level:

The most apparent difference lies in the noise level. Silent compressors are specifically designed to operate quietly, often featuring sound-dampening technology and low-decibel ratings, making them ideal for indoor or noise-sensitive environments. Traditional models, on the other hand, generally produce more noise during operation.

Mechanical Design:

Silent air compressors often use oil-lubricated pumps, which reduce friction and, consequently, lower noise output. Traditional compressors may be oil-free, resulting in louder operation due to more friction in the moving parts.

Size and Portability:

Silent compressors are typically more compact and lightweight, designed for ease of transport and convenience in various settings, including home and office use. Traditional models might be bulkier, catering to industrial or heavy-duty applications.

Power and Performance:

Traditional air compressors usually offer higher power output, which is suitable for demanding tasks and continuous use in industrial settings. Silent models, while efficient, may have limitations on power and air output, making them better suited for lighter tasks.

Cost Implications:

Silent air compressors can be more expensive due to their advanced noise-reduction technology and build quality. Traditional compressors are often more affordable and appealing to those with budget constraints.

Maintenance and Durability:

The maintenance requirements can vary; silent models with oil-lubricated pumps may need regular oil changes, whereas many traditional compressors are designed to be low maintenance.

Application Suitability:

The choice depends on the intended application; silent compressors are preferred in residential, commercial, or noise-sensitive areas, while traditional compressors are chosen for industrial or heavy-duty use where noise is less of a concern.

Key Features to Look for in the Quietest Air Compressors in Australia

When searching for the quietest air compressors in Australia, several key features should be considered to ensure you choose a model that meets your noise level and performance needs. Identifying these features helps in selecting a compressor that is efficient, reliable, compact and suitable for the intended use.

When searching for the quietest air compressors in Australia, several key features should be considered to ensure you choose a model that meets your noise level and performance needs. Identifying these features helps in selecting a compressor that is efficient, reliable, compact and suitable for the intended use.

- Sound Level Rating: The most important feature is the sound level rating, measured in decibels (dB). Look for compressors with a lower dB rating, indicating quieter operation.

- Oil-Lubricated Motor: Air compressors with oil-lubricated motors tend to operate more quietly than oil-free models. The oil reduces friction within the motor, thereby decreasing noise.

- Anti-Vibration Technology: Models equipped with anti-vibration mounts or pads can significantly reduce the noise by minimising vibrations during operation.

- Design and Construction: A compressor’s overall design and construction play a pivotal role in its noise level. A compact design with tightly sealed components can lessen noise. Compressors with a low RPM (revolutions per minute) tend to be quieter.

- Variable Speed Control: Compressors featuring variable speed control allow the user to adjust the motor speed according to the task at hand, which can reduce noise levels when full power isn’t necessary.

- Compact and Lightweight Construction: A compact design can contribute to quieter operation. Additionally, smaller, lightweight models are often less noisy and more suitable for home or small workshop use.

- Efficiency and Reliability: While noise level is a key factor, it should not compromise the compressor’s efficiency and reliability. Ensure the compressor can deliver the required pressure (PSI) and airflow (CFM) for your tools and applications.

- Size and Power Source: Generally, smaller, single-phase compressors tend to be quieter than larger, more industrial models. The power source (electric vs. gas-powered) also influences the noise level, with electric models usually running more quietly.

Application Areas: Best Uses for Quiet Air Compressors

Quiet air compressors have become increasingly popular in Australia due to their versatility and reduced noise levels, making them suitable for various application areas. Understanding the best uses for these compressors can help individuals and businesses select the right compressor model for their specific needs.

- Home Workshops and DIY Projects: A quiet air compressor is ideal for DIY enthusiasts and homeowners with workshops, as it minimises disturbance to household members and neighbours. They are perfect for powering tools like nail guns, staple guns, and airbrushes for small-scale projects.

- Indoor Construction Sites: In indoor construction or renovation sites where noise levels are a concern, quiet air compressors can be used without causing significant disruption. They’re suitable for tasks like trimming and finishing carpentry.

- Automotive Workshops: Auto workshops benefit from quiet air compressors when performing tasks such as tire inflation, bodywork, and engine repairs, where communication among technicians is crucial, and excessive noise can be a hindrance.

- Medical and Dental Clinics: In medical and dental settings, where a calm environment is necessary, quiet compressors are used to power various tools and equipment without causing discomfort to patients.

- Artistic and Craft Applications: Artists and crafters often use quiet air compressors for airbrushing applications. The reduced noise level is advantageous in creative settings that require concentration and precision.

- Commercial Settings: In commercial environments like shops, salons, or offices, where customer comfort is key, quiet compressors can operate in the background without disturbing noise.

- Educational Institutions: Quiet air compressors are suitable for educational settings, such as school workshops, where they can be used without disrupting the learning environment.

Maintenance Tips to Ensure Your Air Compressor Stays Quiet and Efficient

Maintaining your air compressor is crucial to ensure it remains quiet and efficient over its lifespan. Regular upkeep prolongs the air compressor’s life and ensures it operates at optimal noise levels. Here are some key maintenance tips for keeping your air compressor in top condition in Australia.

- Regular Oil Checks and Changes for Oil-Lubricated Models: If your compressor runs on oil, make sure to check the oil level frequently and replace it as recommended by the manufacturer. Reducing noise from friction and ensuring smooth operation are two benefits of clean oil.

- Air Filter Maintenance: Keep the air filter clean and replace it when necessary. A clogged air filter forces the compressor to work harder, increasing noise levels and reducing efficiency.

- Tighten Loose Parts: Periodically check for and tighten any loose screws, bolts, or fittings. Vibrations from normal operation can loosen these parts over time, increasing noise and potential damage.

- Leak Checks: Regularly inspect hoses and fittings for leaks, as air leaks can cause the compressor to cycle more frequently, increasing noise and reducing efficiency.

- Proper Storage: Store your compressor in a clean, dry environment to prevent rust and corrosion. Moisture can cause internal component damage and increase operating noise.

- Belt Tension Adjustment: For compressors with a belt drive, ensure the belt tension is correctly adjusted. An excessively tight belt can put stress on the motor, while a loose belt might cause slippage and noise.

- Routine Professional Servicing: Have your air compressor professionally serviced at intervals recommended by the manufacturer. Professional servicing can identify and rectify issues that may not be apparent to the average user.

In conclusion, it is crucial to prioritise noise reduction and performance when it comes to finding the quietest air compressor in Australia. Investing in a high-quality, reliable air compressor brand known for its quiet operation can ensure a peaceful working environment without compromising efficiency. Take your time to compare different models, read customer reviews, and consider which fit your specific needs and budget. Remember, the quietest air compressor the more it will provide you with superior performance and contribute to a more comfortable and enjoyable working experience.

For expert advice and a wide selection of the quietest air compressors in Australia, don’t hesitate to contact us. Call Cattani Compressors Australia at (02) 8880 9257. Our knowledgeable team is ready to assist you in finding the perfect air compressor that meets your needs for low-noise operation without compromising on performance. Let us help you make a choice that suits your requirements perfectly. Call us today to explore our range and make an easy and informed decision for your business or personal use!

References

Compressor Noise – Chicago Pneumatic

https://compressors.cp.com/en-us/compressor-noise

Types of Air Compressors – Atlas Copco

https://www.atlascopco.com/en-ae/compressors/types-of-air-compressors

Different Types of Air Conditioning Compressors

https://www.compressorsunlimited.com/blog/different-types-of-air-conditioning-compressors

Best Quiet Air Compressors – Thomasnet

https://www.thomasnet.com/articles/machinery-tools-supplies/best-quiet-air-compressors/

Quiet Air Compressor Installation – Atlas Copco

https://www.atlascopco.com/en-eg/compressors/variable-speed-compressors/quiet-air-compressor-installation